Individual steel solutions

Welded structures have no limits. Our designers will create and the welding department will manufacture any structure.

Sometimes modular solutions, such as the Flexlean tube-and-connector system or the Flexlean aluminum profile system, will not meet the customer’s requirements. Such structures can be, for example, the hangers on which semi-finished products go into paint baths. Sometimes other requirements also result in the need for welded components in production spaces. At Flexlean, using advanced design tools such as Solidworks, we can design any structure from scratch.

First, we ask our partners many questions that allow us to understand the purpose of the structure being designed. As a result, you receive a proposed solution that responds to the inquiry presented to us. We ourselves take care of the selection of material and additional elements (wheels, shelves, hooks, etc.).

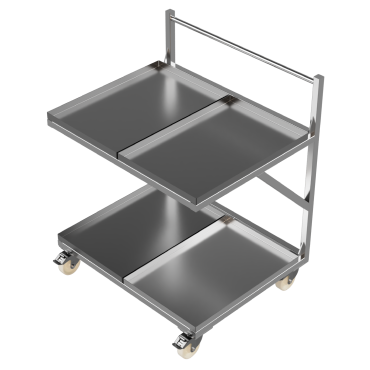

The design accepted by our partners goes to the welding department where the process of their production begins. Ultimately, many of the manufactured elements go to the powder paint shop of our partnered contractor. The exceptions are stainless steel structures, which do not require varnishing.

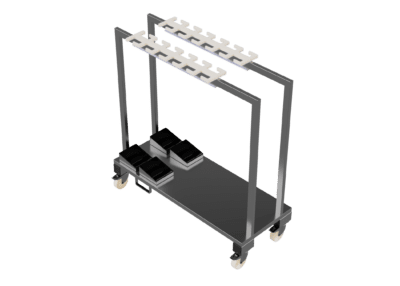

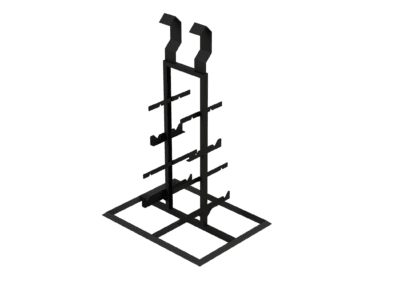

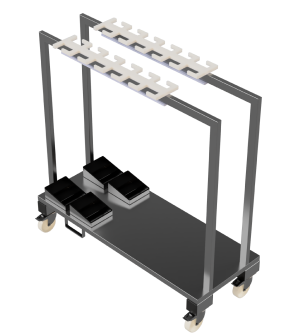

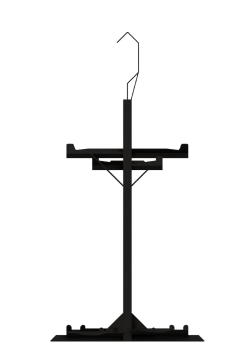

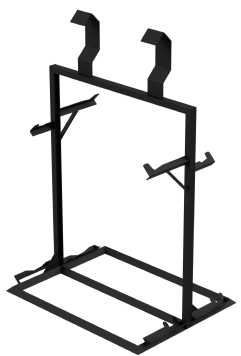

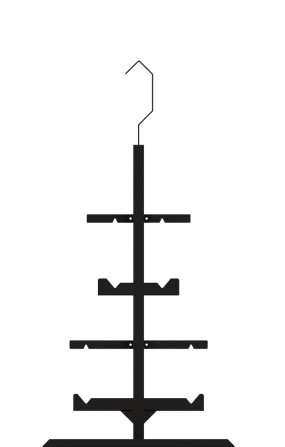

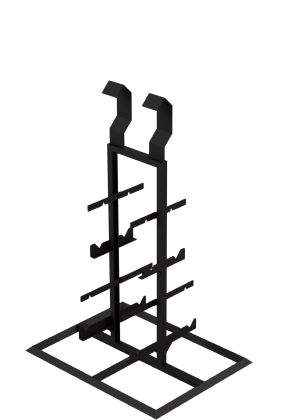

Example projects

Below are some examples of the most commonly built structures. For more information go to the projects tab.

FAQ

Does Flexlean have its own welding shop or does it use sub-suppliers?

All structures are built in our welding shop and carried out by our welders. Everything is done in consultation with the designer, who is responsible for the design of the structure.

Does Flexlean make stainless steel structures?

Yes, we do.

Can welded structures include tube-connector system components such as roller bars?

Yes, within Flexlean we have experience in implementing many solutions. We combine systems to ensure maximum efficiency.