Pipe and connector system

Pipe and connector system

- saves space and increases productivity

- helps implement lean philosophy

- modularity makes it easy to rebuild it when changes are needed

The easiest way to build structures that streamline production processes or simply facilitate the development of any area.

The tube-and-joint system was developed in the 1970′s by the Japanese. At first it was used only by Toyota plants. When the concept of “lean production” spread around the world this system appeared in every modern plant and serves as a tool for building structures to streamline processes or as an excellent system for simply organizing space. Just as a closet needs shelves for underwear, shirts, suits, hats, gloves, jewelry…., production needs structures for assemblers, tool racks, or shelving space for products. We also have experience in the development of private spaces, such as garages.

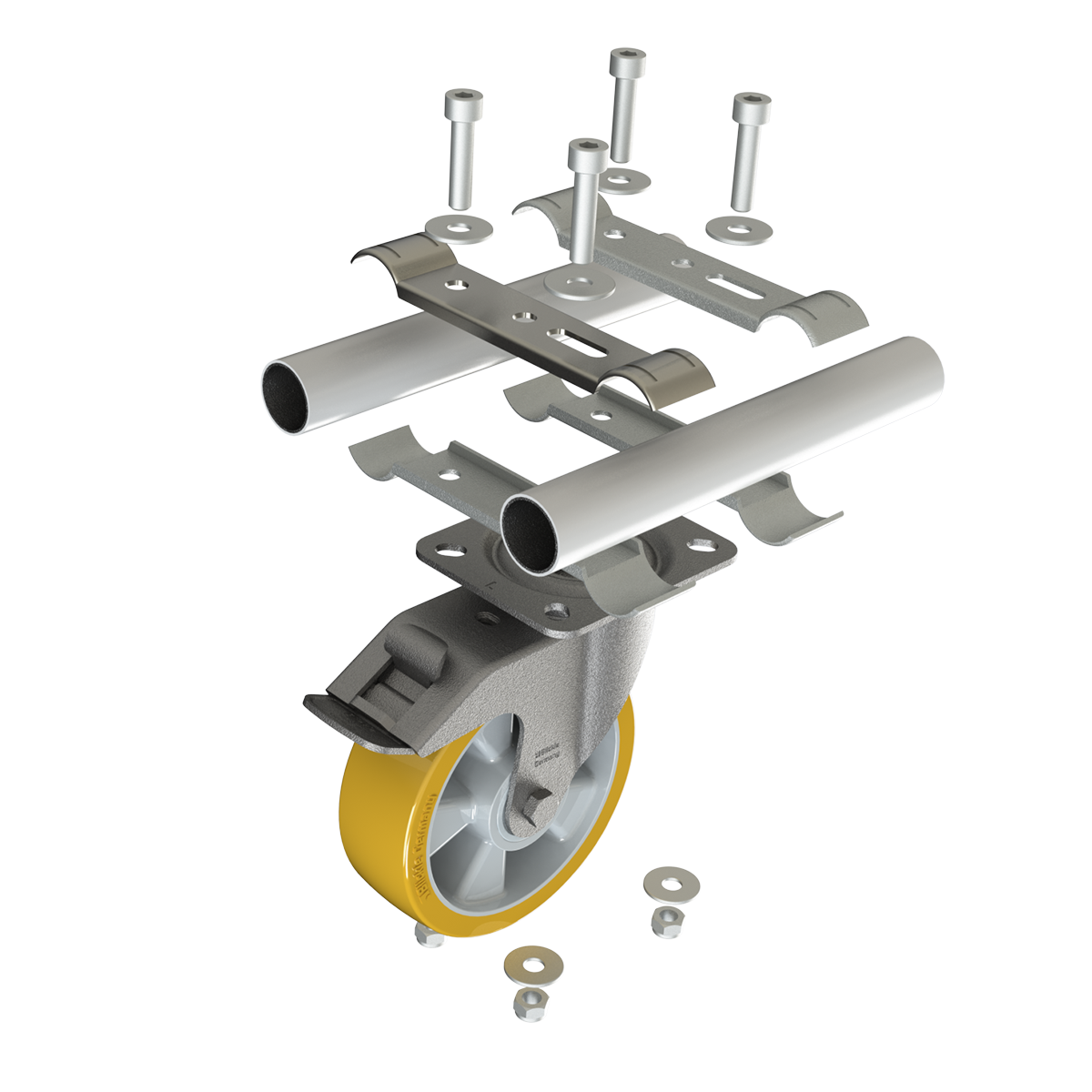

The whole system is based primarily on various types of pipes. We offer ABS-coated pipes, which are characterized by very high scratch and corrosion resistance. The assortment we have prepared also includes nickel-plated pipes, as well as ESD anti-static pipes. Of course, pipe systems would not work without all kinds of connectors, roller tracks ( also available in ESD version), as well as wheels with different load capacity, further increasing the mobility.

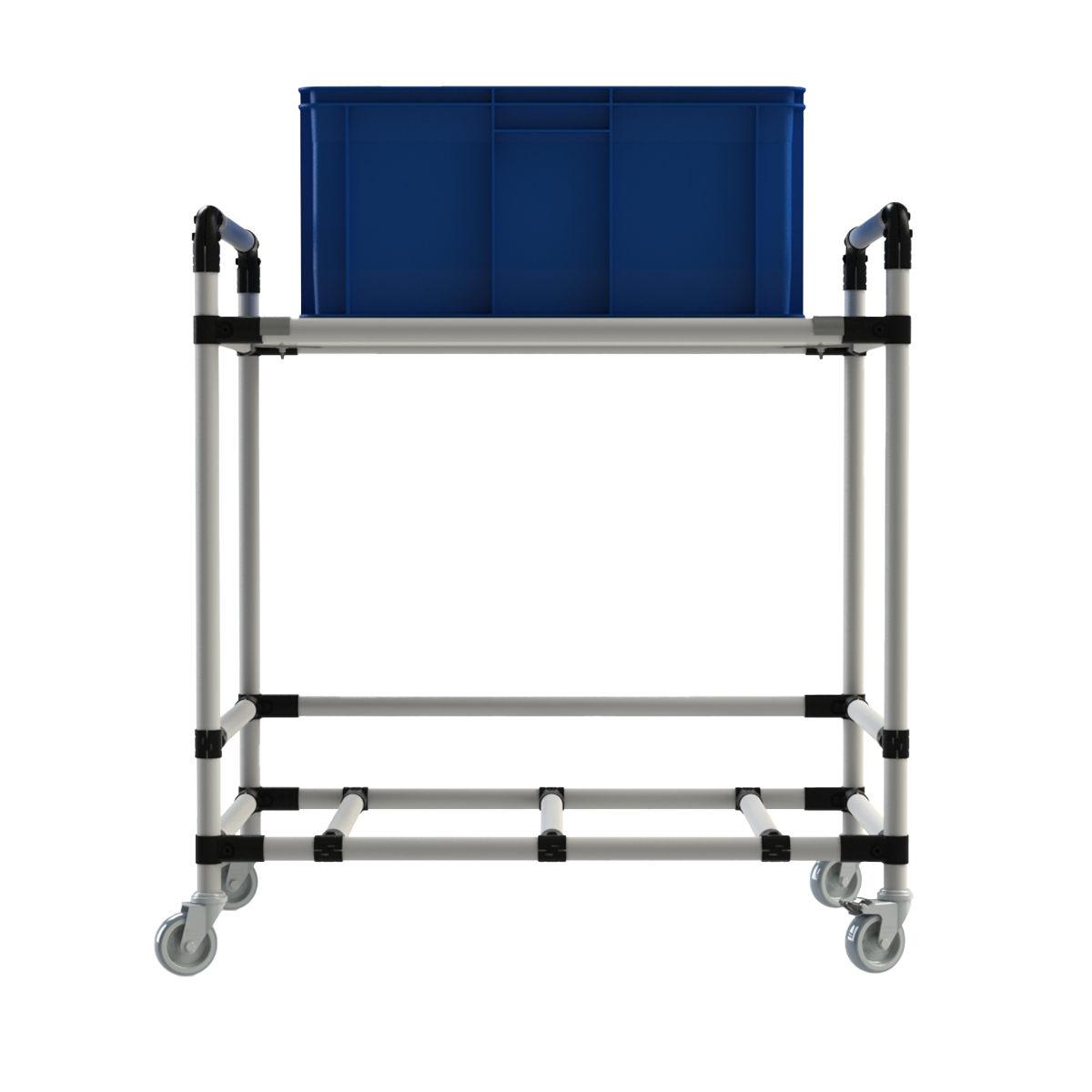

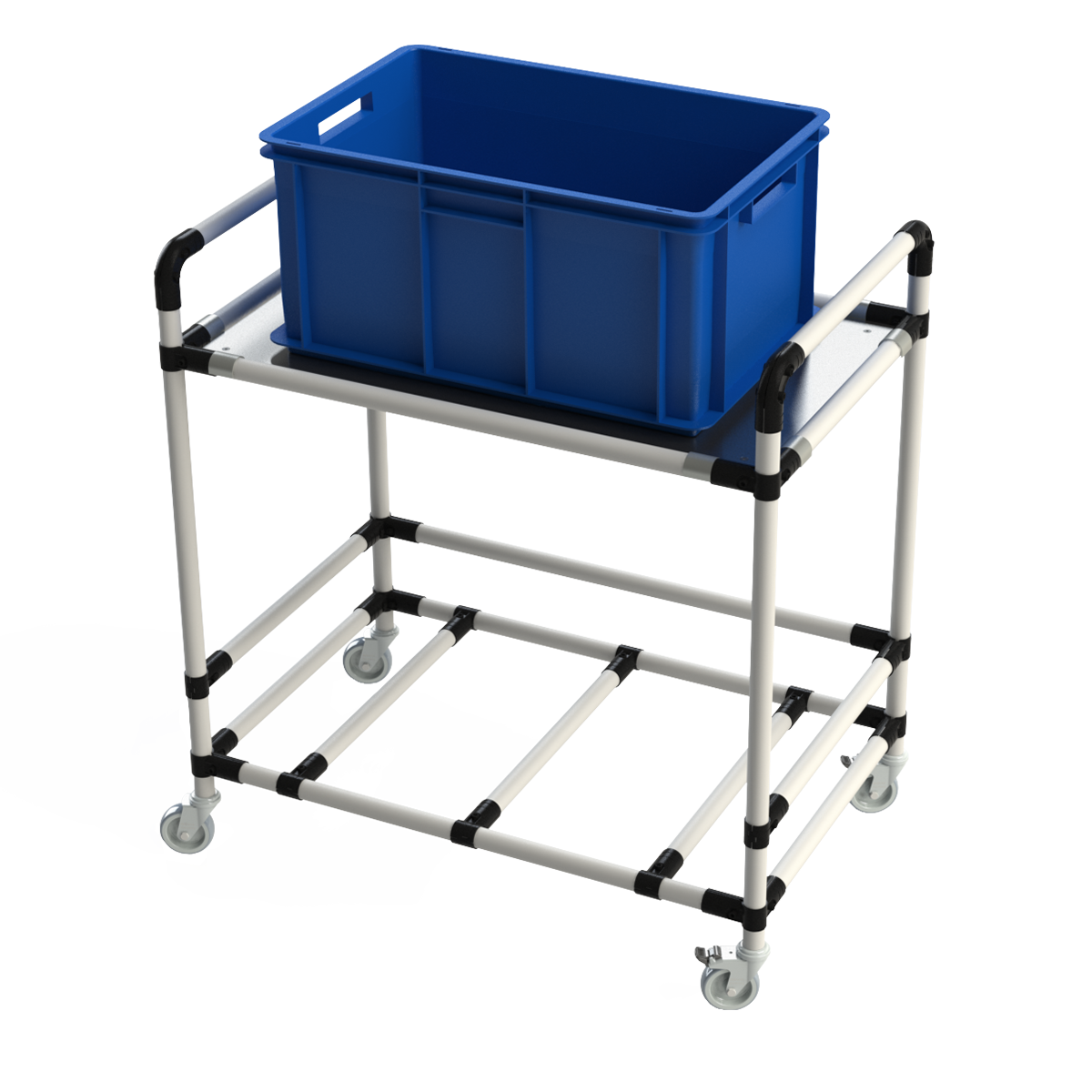

We know perfectly well how important intralogistics is for the proper functioning of the company. The efficient flow of products within the company allows to optimize operations and increase efficiency. Pipe systems are the perfect solution for internal logistics. Fitted structures placed on wheels improve the flow of goods and ensure better organization of work.

Example projects

Below are some examples of the most commonly built structures. To get more go to the projects tab.

Workstation

Mobile workbench

Multi-level supply cart

FAQ

Are special tools needed to build the structure?

All you need to have is a saw (it can be a regular hand saw for metal, a band saw, and as a last resort also an angle grinder) and a 5mm allen wrench. That's all.

Is a design needed to build the structure?

A blueprint, even one made by hand, helps rember about important structural elements (such as bevels). It's easier to assemble "Legos" by seeing the car assembled.

If you have trouble designing your construction, come to us. We will certainly help you.

Can I order components for self-assembly?

Of course you can. If you have any doubts about the selection of components, please contact us. We will certainly help you.

However, if you decide to order a ready-made structure then we will be happy to design it for you and provide a list of components necessary for assembly.

What is the diameter of the supporting elements (pipes) and what material are they made of?

The pipes have an outer diameter of 28mm. They are made of seamed galvanized steel pipe and coated with ABS plastic.